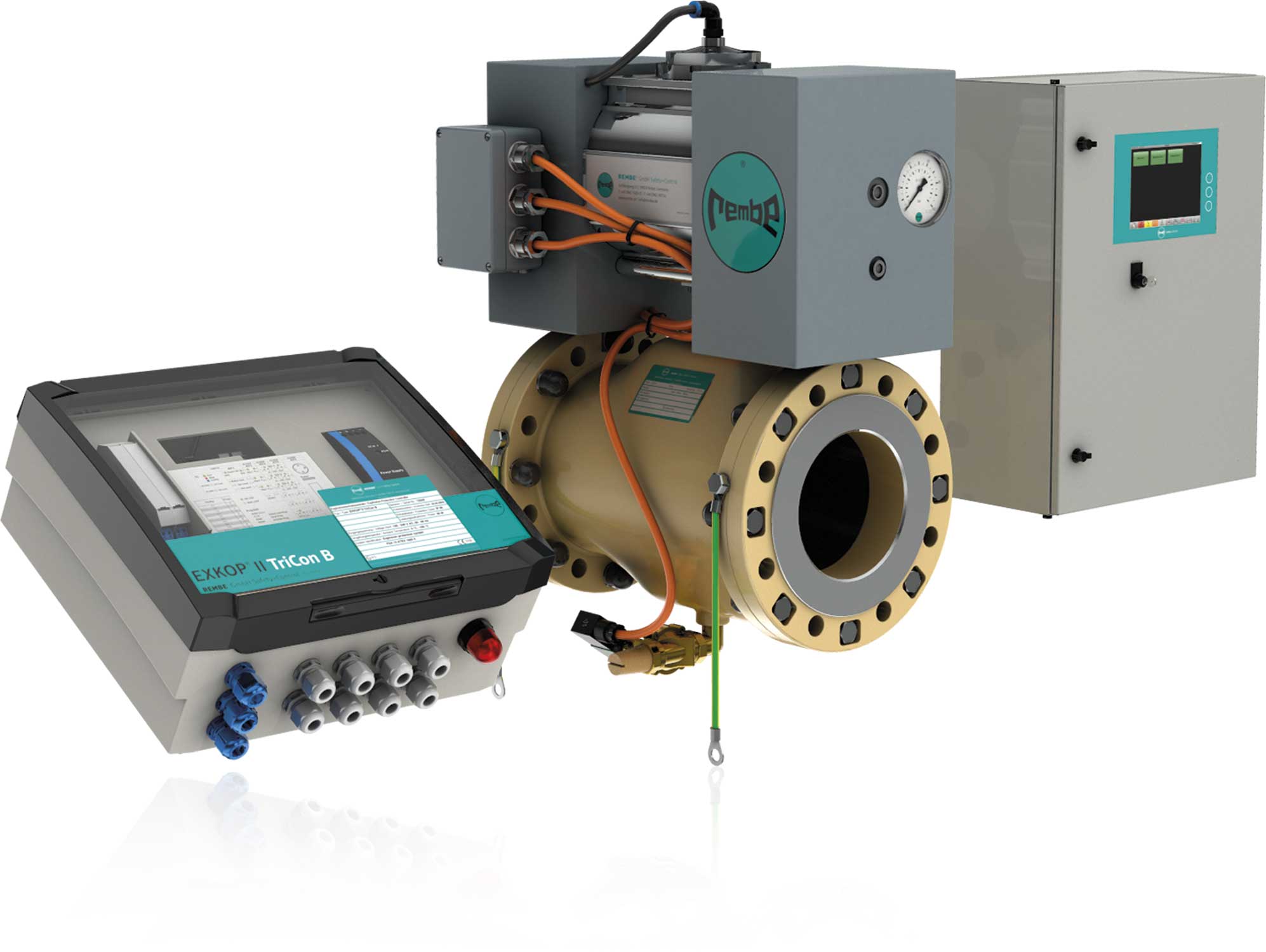

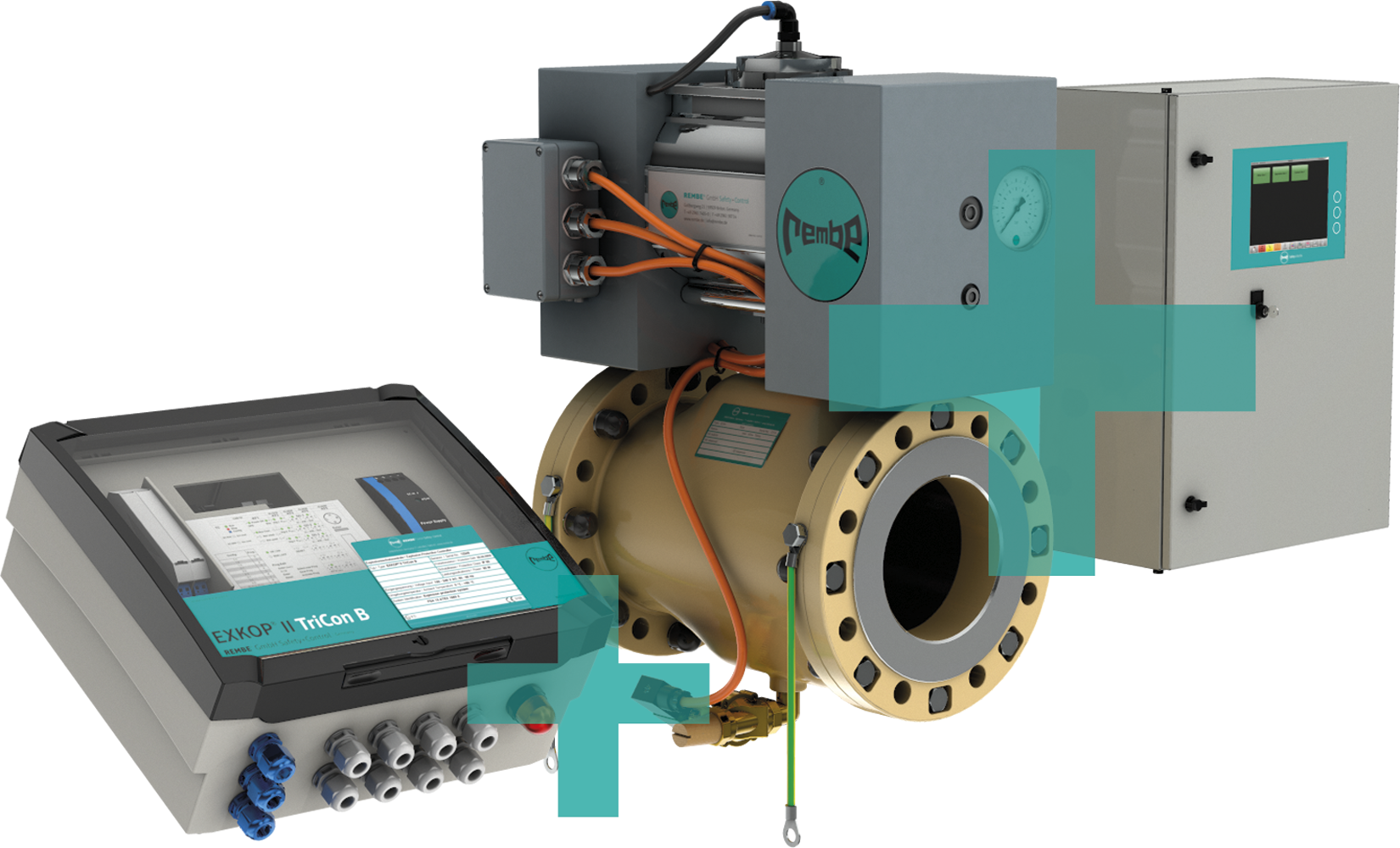

EXKOP® System

Space-saving, bidirectional isolation.

This system isolates plant components in both directions and consists of a self-monitoring EXKOP® controller with data storage and one or several quench valves.

Application

EXKOP® systems are suitable for filling lines, aspiration lines and pipes, pneumatic conveyor lines and air intake openings. As well as operating as a decoupling system for powder handling system, the EXKOP® system can also be used as a spark arrester or overpressure limiter.

Advantages

-

Effective protection through high-speed detection of explosion events.

-

Returns to operation again immediately after triggering.

-

Self-monitoring safety electronics with operating data storage.

-

Modem-compatible remote system analysis permits remote maintenance.

-

Instant recognition of system status in HMI.

-

Instant status forwarding to customer PLC (Alarm, failure, maintenance, etc.).

-

Processes wide range of trigger signals for easy retrofitting to existing plants.

-

Fail Safe mechanism automatically closes the valve if the power / compressed air fails or the valve is manipulated.

-

Reliable, process-optimized protection against explosions in adjacent plant components.

-

Minimal downtime after the mechanism is triggered.

Mechanism

In the event of an explosion, the EXKOP® controller receives a trigger signal (e.g. from the signaling unit of the Q-Rohr® or an explosion vent, from a pressure switch or spark detector) and activates the connected EXKOP® quench valves. The quench valves close within a few milliseconds and thus protect interconnected plant components. After being triggered, the quench valves can be put back in operation once again at the touch of a button.

Combinations

EXKOP® Controller

| Product | up to 3 quench valves | more than 3 quench valves | configurable in- und outputs | Q-BicTM | Explosion Slide Valves REDEX, RSV |

|

|---|---|---|---|---|---|---|

| EXKOP® II TriCon | ||||||

| EXKOP® Express |

Can only be used in special cases, only QV II.

EXKOP® quench valves

| Product | pipe diameter up to 250 mm | pipe diameter greater than 300 mm | installation in hygienic processes |

|---|---|---|---|

| EXKOP® QV II | |||

| EXKOP® QV III |

Applications + Industries

-

animal feed productions

-

aspiration plants

-

brewery

-

conveyors

-

destoners

-

elevators

-

filters

-

food

-

food production

-

mills and grinding plants

-

mixers

-

recycling

-

screens

-

silo

-

spray dryers

-

wood processing

Certifications

Certified in

accordance with

EN 16009

EN 14797

EN 14797

ATEX EC type

examination certificate no. FSA 04 ATEX 1537 X

ATEX EC type

examination certificate no. FSA 15 ATEX 1659 X

The EXKOP® system is ideal in combination with explosion vents or flameless explosion venting solutions.

REMBE® EXKOP® QV III

at the production.

REMBE® EXKOP® QV III

at the production.

Click and drag image to view.

The dimensions shown may differ from those of the actual product.

* Requires iOS 13, iPadOS 13, ARCore 1.9 or higher.

* Requires iOS 13, iPadOS 13, ARCore 1.9 or higher.

Unboxed - EXKOP® Maintenance

Cindy Baumann, REMBE® CAD-Expert

"The EXKOP® is available in a range of standard sizes, though we keep getting requests for custom solutions. The biggest quench valve we’ve built so far has a nominal width of 1000 mm."

Any Questions?

We would be happy to show you solutions tailored to your process that limit the effects of an explosion to a harmless level and ensure that production can be resumed quickly after an explosion event.